-

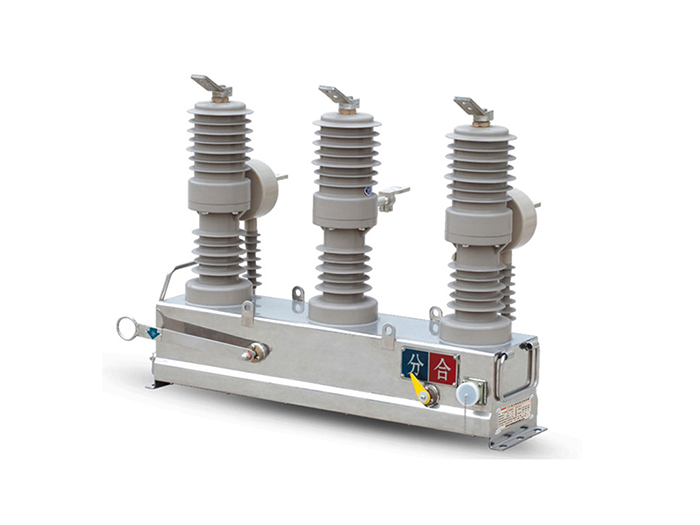

ZW32-12 0utdoor HV Vacuum Circuit Breaker

-

S11 Series 10KV Distribution Transformer

-

ZN85-40.5 Indoor HV Vacuum Circuit breaker

-

S10 Series 10KV Distribution Transformer

-

Single-phase Oil Immersed Transformer

-

ZW8-12,ZW8-12G Hv Vacuum Circuit Breaker

-

VS1(ZN63) H.V Vacuum Circuit Breaker

-

SC(ZB)10 Series 10KV Dry Transformer

-

VS1-12 Type Side-Mounted(Vbm7) Vacuum Circuit Breaker

Product Advantage

Backed by decades of expertise, YIFA provides a complete range of High Voltage Products including High Voltage Transformers, Substations, Ring Main Units, Switchgear, and HV Vacuum Circuit Breakers. These products are widely applied in power generation, transmission, distribution, industrial, and renewable energy sectors, ensuring reliable performance under demanding operating conditions.

-

Comprehensive Portfolio

A full spectrum of high voltage solutions to meet diverse industry needs, from grid infrastructure to industrial power systems.

-

Proven Safety & Reliability

Designed and tested to meet international standards, ensuring safe operation, reduced downtime, and long service life.

-

Tailored Engineering Solutions

Fit-for-purpose product designs that adapt to customer requirements across power, transmission, distribution, and renewables.

-

Efficient Project Delivery

From conceptual design to commissioning, YIFA products are supported by a skilled team of industry specialists to guarantee quality and on-time completion.

Cases

Frequently Asked Questions

-

What are the signs and causes of insulation aging/breakdown in high-voltage equipment?

Signs: Increased leakage current, localized overheating, abnormal discharge sounds.

Causes:

Long-term electrical stress degrading materials.

Environmental factors (humidity, pollutants like salt/dust).

Overvoltage surges (lightning, switching operations).

Solutions:

Perform regular dielectric loss testing (tanδ) and partial discharge detection.

Upgrade to weather-resistant insulation materials (silicone rubber, epoxy resin).

Install surge arresters and overvoltage protection devices. -

How to address corona discharge in high-voltage conductors?

Signs: Visible blue-purple glow, ozone odor.

Causes: Sharp edges/small curvature radii causing electric field concentration.

Solutions:

Optimize grading ring design for uniform electric field distribution.

Apply anti-corona coatings (e.g., semi-conductive paint).

Clean conductor surfaces regularly to remove contaminants. -

Why do circuit breaker switching mechanisms jam, and how to fix this?

Signs: Delayed opening/closing, abnormal vibrations.

Causes:

Aged lubricant or contamination ingress.

Component wear (spring fatigue, gear deformation).

Solutions:

Use fully sealed designs to block dust.

Conduct mechanical characteristic tests every 3 years (operation timing, bounce time).

Replace parts with self-lubricating bearings or ceramic-coated components.

-

How to prevent sealing failures in SF6 gas/oil-immersed equipment?

Signs: SF6 gas leakage, oil leakage in oil-immersed equipment.

Causes:

Degraded seals (temperature cycling causing rubber cracks).

Uneven flange installation stress.

Solutions:

Adopt dual-seal designs with leakage monitoring sensors.

Replace rubber seals with metal bellows for critical joints.

Monitor gas pressure/oil levels routinely. -

What causes overheating at electrical contact points?

Signs: Infrared shows contact temperatures >80°C.

Causes:

Increased contact resistance (oxidation, loosening).

Overloading beyond rated current.

Solutions:

Use silver-plated contacts to reduce resistance.

Install wireless temperature sensors (e.g., CT-powered modules).

Implement forced-air or water cooling. -

How to resolve poor heat dissipation in transformers?

Signs: Oil temperature >95°C in oil-immersed transformers.

Causes: Clogged radiators, fan failures, or inadequate ventilation.

Solutions:

Clean annually; upgrade to variable-frequency smart fans.

Add heat pipe systems or auxiliary air conditioning. -

How to prevent condensation/icing in high-voltage enclosures?

Signs: Water droplets on inner walls, reduced insulation performance.

Solutions:

Install auto-heating/dehumidification systems.

Use aerogel insulation to block external cold sources.

Design enclosures with sloped tops to prevent water accumulation. -

How to mitigate corrosion and pollution flashovers?

Signs: Rust on metal parts, pollution-induced flashovers on insulators.

Solutions:

Use 316L stainless steel or aluminum alloy coatings in coastal areas.

Apply RTV silicone coatings (hydrophobic surfaces).

Perform live-line washing periodically. -

What technologies enable predictive maintenance for high-voltage systems?

Solutions:

Deploy multi-sensor monitoring (DGA for oil analysis, high-frequency partial discharge detection, vibration sensors).

Use AI models trained on historical data to predict failures 2–3 months in advance.

Follow standardized protocols (e.g., *DL/T 596 Power Equipment Preventive Test Code*). -

A 500kV GIS reports frequent partial discharge alarms. How to diagnose and resolve this?

Diagnosis: Ultrasound testing locates surface burrs on disconnector contacts.

Solution: Polish contacts during outage, apply conductive grease. Post-repair discharge levels drop to <5pC (meets national standard <20pC).