Transformer substations are the backbone of modern power transmission and distribution systems. They are engineered facilities that transform voltage levels, control power flow, isolate faulty sections, and ensure stable and reliable electricity delivery across cities, industries, and infrastructure. As global energy demand continues to rise and smart grid development accelerates, understanding the different types of transformer substations becomes essential for planners, electrical engineers, and industries seeking efficient and eco-friendly power solutions.

This article provides a comprehensive overview of the major categories of transformer substations, classified by voltage level, function, installation structure, design type, and application scenario.

Voltage level is the most fundamental way to classify transformer substations. It determines a station’s role within the power grid and the scale of power it handles.

High-voltage substations form the core of regional transmission networks. They connect major power plants to large urban or industrial load centers. These substations must handle massive power flows, provide high reliability, and support long-distance transmission with minimal loss. High-voltage sites often incorporate advanced protection systems, GIS equipment, and robust automation.

Medium-voltage substations bridge the gap between transmission and distribution systems. They step down transmission-level voltage to levels suitable for local distribution networks. These stations are common near industrial areas, towns, and commercial districts.

Low-voltage substations supply power directly to residential areas, commercial buildings, retail districts, and small factories. They are compact, efficient, and designed for high accessibility, making them key components of urban and rural distribution networks.

Transformer substations can also be grouped according to their operational purpose in the grid.

Located at power generation sites, step up transformer substation increase the voltage of electricity before sending it across transmission lines. Higher voltage reduces line losses and enables efficient long-distance transmission. These are essential for large thermal plants, hydroelectric stations, solar farms, and wind farms.

Step down transformer substation reduce transmission-level voltage to lower, safer levels appropriate for consumers or industrial operations. They are strategically positioned near major load centers and industrial zones.

Distribution transformer substations further step down the voltage (usually to 10 kV or below) and feed local distribution lines that supply homes, shops, offices, and light industries. They play a direct role in ensuring power quality for end-users.

Unlike other types, switching substations do not contain transformers. Their function is to route and control power flow through various transmission lines. They are crucial nodes for grid reliability and allow operators to isolate faults, reroute electricity, or perform maintenance.

These substations perform AC–DC or DC–AC conversion, enabling integration with HVDC transmission systems or providing DC power for specific industrial equipment. With the growing use of HVDC technology in long-distance and underwater transmission, converter substations are becoming increasingly important.

The physical structure and installation environment significantly influence the design and equipment used in substations.

Indoor transformer substations are housed within buildings, providing environmental protection, improved safety, and reduced noise. They are ideal for dense urban environments where space is limited or where aesthetic considerations matter, such as commercial districts and residential neighborhoods.

Outdoor transformer substations are commonly used in high-voltage transmission systems due to their lower construction cost and easier maintenance access. Equipment such as transformers, circuit breakers, and isolators are installed in open air with appropriate weatherproofing.

Underground transformer substations are hidden beneath city plazas, shopping centers, or transportation hubs. They minimize surface space usage and preserve urban aesthetics. Their construction is complex, requiring advanced ventilation, fire protection, and waterproofing systems.

Mobile transformer substations are transportable units mounted on trailers. They provide temporary power during emergencies, natural disasters, grid maintenance, or for rapid deployment in remote or underserved regions. Their flexibility makes them valuable in disaster relief and fast-growing industrial zones.

Each design style serves specific engineering needs, especially in modern and high-density environments.

These substations follow a traditional layout with separate transformers, switchgear, and control rooms. They are reliable, easy to maintain, and widely used across various voltage levels.

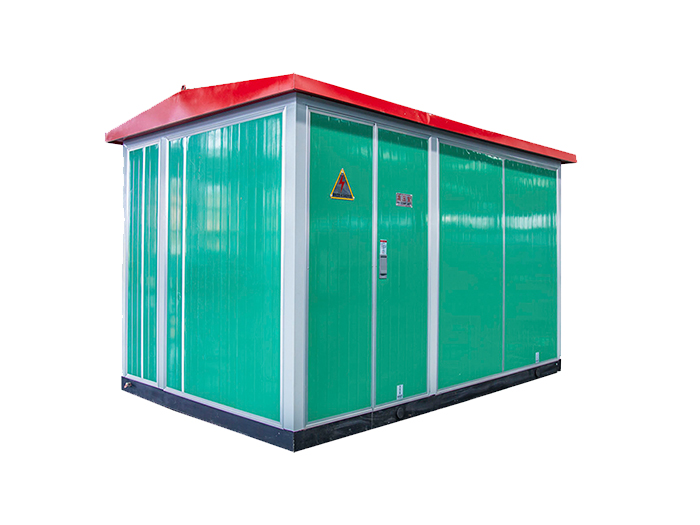

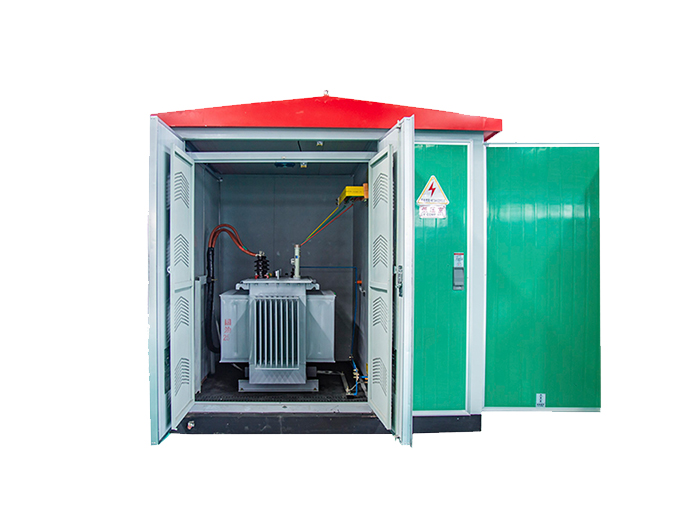

Also known as packaged or kiosk substations, these units integrate transformers, switchgear, and protection systems into a single enclosure. They are widely used in new urban developments, smart cities, commercial complexes, and industrial automation projects due to their small footprint, safety, and rapid installation.

GIS technology uses SF₆ gas for insulation, enabling extremely compact substation footprints. GIS offers high reliability, excellent environmental resistance, and minimal maintenance. It is ideal for high-voltage applications in cities, coastal regions, and harsh environments.

Hybrid substations combine the benefits of both air-insulated (AIS) and gas-insulated (GIS) equipment. They provide flexibility in layout, reduced land usage, and cost advantages compared to full GIS systems.

Different environments and industries require specialized substation designs.

Designed for compactness, noise control, and safety. Often incorporate GIS or underground designs to reduce land footprint.

Require high reliability and cost-effective construction. Outdoor AIS designs are common due to abundant land and lower environmental constraints.

Customized stations designed to support heavy loads, high-capacity equipment, and unique voltage requirements. They feature reinforced protection systems and robust reliability.

Built for solar, wind, and hybrid energy projects. Include step-up transformers, power factor correction, and smart monitoring systems to manage intermittent power flow.

Include substations for railways, metros, airports, and EV charging infrastructure. These require specialized protective schemes and real-time monitoring to ensure operational stability.

Regardless of type, all substations contain several essential components:

Power transformers

Switchgear (AIS / GIS)

Circuit breakers and isolators

Relays and protection systems

Busbars and conductors

Surge protection and grounding systems

SCADA, automation, and monitoring equipment

These components work together to maintain safety, reliability, and efficient power flow.

Transformer substations play an essential role in the safe and efficient operation of electrical grids. From high-voltage transmission hubs to compact urban stations and renewable energy substations, each type serves a unique function. Understanding the different classifications helps engineers, planners, and industries choose the right substation type to ensure power quality, reliability, and long-term operational efficiency. As digitalization, electrification, and sustainability continue to shape the power sector, modern substations will remain central to building the intelligent grids of the future.

YIFA Holding Group is a national high-tech enterprise dedicated to intelligent and eco-friendly industrial electrical solutions. With expertise spanning industrial electrical components, smart power distribution, and automation technologies, YIFA also operates across finance, e-commerce, trade, and investment. The company is committed to delivering innovative, reliable, and sustainable electrical products that support the development of modern power infrastructure and smart energy systems.