Intelligent integrated transformer substation

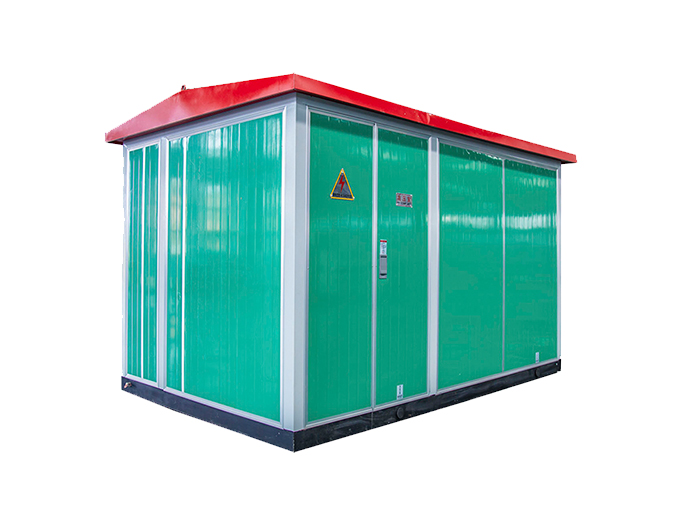

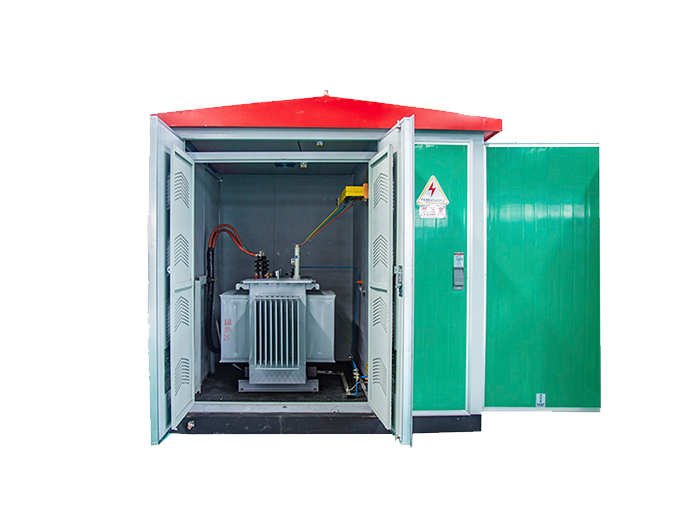

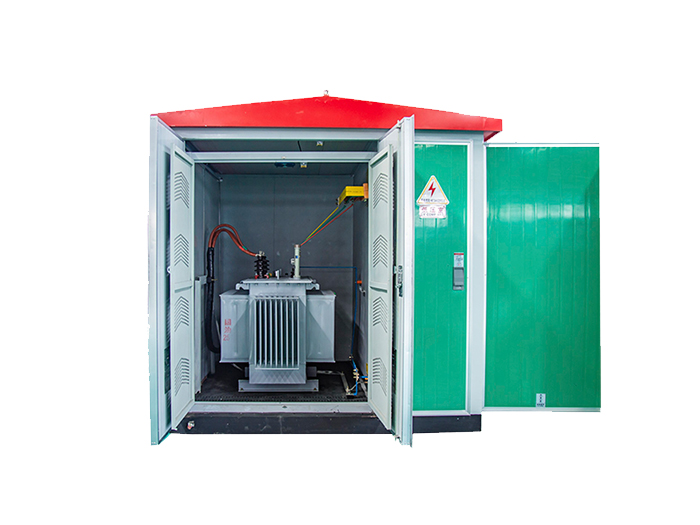

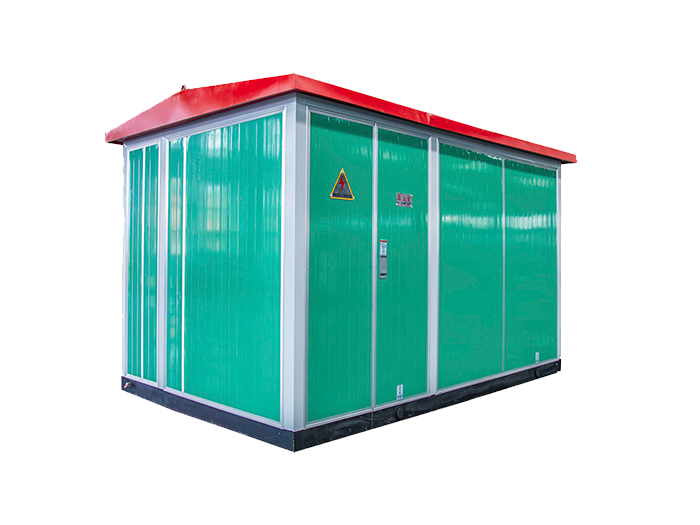

Enclosure Structure & Mechanical Design

Framework Construction

The enclosure section is fabricated from channel steel (C-section) and angle steel, providing high mechanical strength (meets IEC 62271-200 seismic class I requirements).

External cladding utilizes anodized aluminum alloy panels (or optional steel/composite alternatives), featuring:Smooth, flat surface finish for aesthetic appeal

Enhanced corrosion resistance (ISO 9227 salt spray tested)

Base & Access Design

Base frame elevated 300–600 mm above foundation level to prevent water ingress.

All doors swing outward with:Opening angle >90° (equipped with positive stop devices)

Integrated handles and concealed, weatherproof latches (IP54-rated, corrosion-resistant)

Fully sealed, tamper-proof enclosure design per IEC 62271-202 security requirements.

Specification Parameter

Technical parameters table

Nominal voltage kV 12 12

Rated currentA630630

Power frequency withstand voltage within 1 minute kV 42 42

Lightning impulse withstand voltage (BIL) kV95 95

Direct current withstand voltage within 15 minuteskV53 53

Power frequency withstand voltage within 1 minute under zero voltage kV 38 38

Power frequency withstand voltage of the second circuit (within 1 minute)V 2000 2000

Power supply voltage for electric operating V DC24 Dc24

Breaking current under rated load A630

Charging breaking current under rated cable A10 25

Breaking current ünder rated short circuit kA20

Making current under rated short circuitkA5050

Withstand current for 3 seconds under rated short circuit kA2020

Withstand current under rated peak kA5050Mechanical life/time 10,000 10,000

SF6 gas rated pressure (20℃) Mpa 0.035 0.035

Annual leakage rate of SF6 gas % <0.1<0.1

Product Advantage

Thermal Management

Natural ventilation system with optimized airflow channels and thermal insulation barriers ensures:All electrical components operate below maximum allowable temperatures (per IEC 60076-2)

Prevention of condensation under ambient temperature variations (−25°C to +40°C)

Dedicated Grounding System

Copper grounding conductor (min. cross-section 30 mm², current density ≤200 A/mm²) installed throughout the enclosure.

Grounding terminals:≥2 fixed connection points for grounding grid (clearly marked with IEC 60417-5019 symbol)

Copper bolts (min. diameter 12 mm, metric thread M12)

Performance requirements:Withstands maximum short-circuit current without thermal damage (per IEC 60909)

Dynamic and thermal withstand capability matched to HV switchgear grounding configuration (tested per IEC 62271-1 Annex BB)

Ensures no hazardous temperature rise on adjacent structures during fault conditions

Outline And Mounting Dimensions