Research And Development Capability

General project manager

Yu Jinqing

Graduated from the School of Physics and Microelectronics of Hunan University

Professor, doctoral supervisor

In-depth research in the fields of terahertz, power intelligence and sensing technology

He has presided over more than 20 national research projects

Software Engineer

Song Zihao

Hunan University professor level senior engineer. published more than 50 journal research papers in top journals in the field of artificial intelligence.

Tech-Director

Wen Huihui

General manager of HV division and chief engineer of the company.

Product Designer

Zheng Boyang

Graduated from the University of Miami. company general manager and technical director of technology R&D center, mainly responsible for product design.

Designer

Song Jian

Mainly responsible for the process realization of products, and participate in the transformation projects of scientific.Productive Capacity

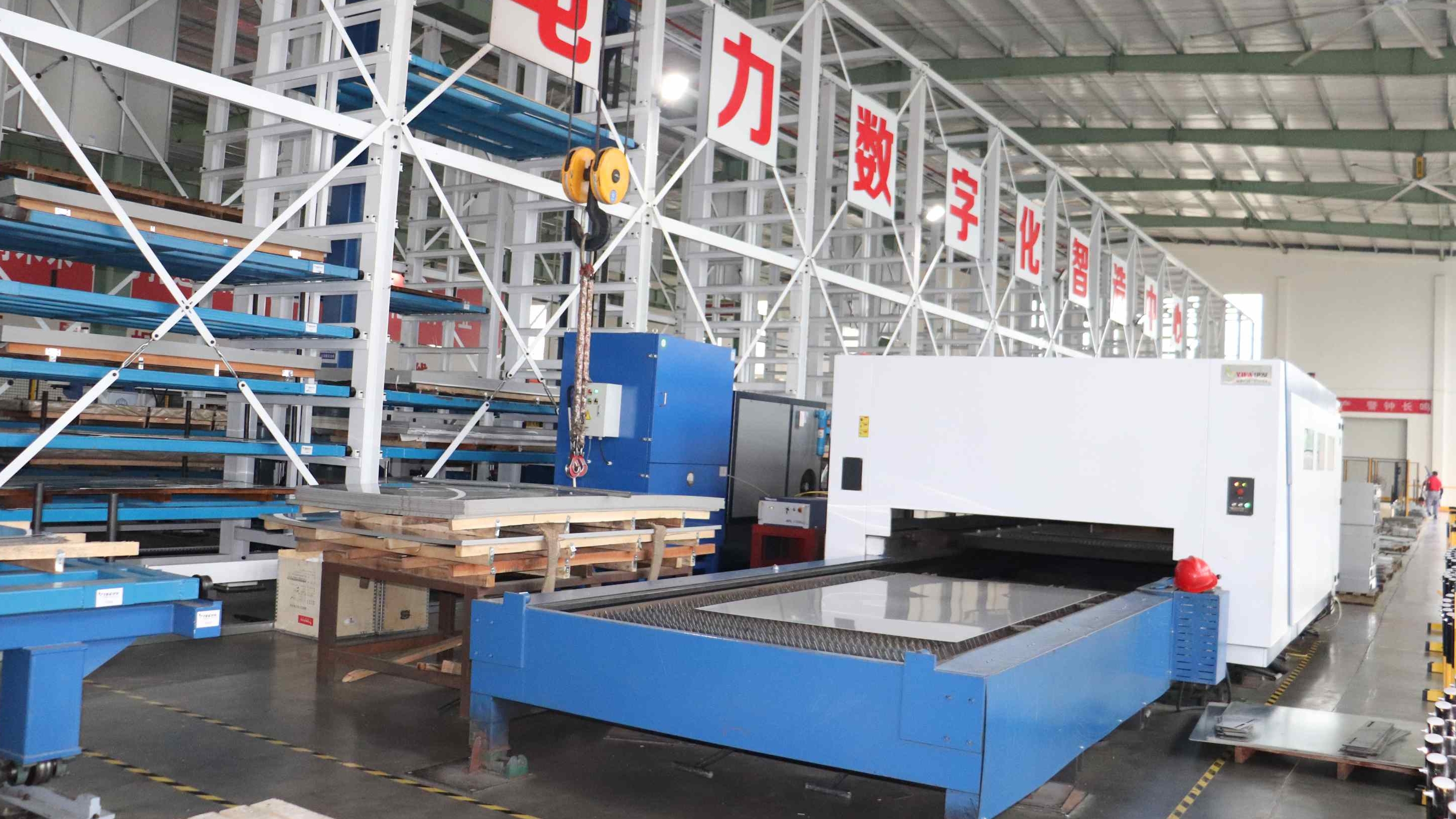

Production Base

-

JIANGXI PRODUCTION BASE: 200000 ㎡

-

WENZHOU PRODUCTION BASE: 20000㎡

Production Equipment

- Miniature Circuit Breaker

- Transformer

- Ring Cabinet

-

Selection and inspection of raw materials

Select high-quality raw materials that meet national standards, such as high temperature plastic with good flame retardant performance for the shell, high conductivity materials such as copper and copper alloy for internal conductive parts, and high quality magnetic materials for electromagnetic components. Strict inspection and screening of raw materials to ensure their quality.

-

Processing and forming

The metal shell is processed by stamping, bending and other processes to meet the design requirements of the shape.

Accessories such as contacts and springs are machined to the desired shape. -

Assemble

The finished metal shell and accessories are assembled, and the parts are joined together using screws and other fixings.

Install wires and connectors for connection to the circuit. -

Test

The functional and safety performance of the assembled circuit breaker is tested by professional testing equipment. The test content mainly includes overload protection ability, short circuit protection ability, rated current and rated voltage detection. Only after passing the strict test, can the next step of packaging and delivery.

-

Selection and inspection of raw materials

Select high-quality raw materials that meet national standards, such as high temperature plastic with good flame retardant performance for the shell, high conductivity materials such as copper and copper alloy for internal conductive parts, and high quality magnetic materials for electromagnetic components. Strict inspection and screening of raw materials to ensure their quality.

-

Processing and forming

Select high-quality raw materials that meet national standards, such as high temperature plastic with good flame retardant performance for the shell, high conductivity materials such as copper and copper alloy for internal conductive parts, and high quality magnetic materials for electromagnetic components. Strict inspection and screening of raw materials to ensure their quality.

-

Assemble

Select high-quality raw materials that meet national standards, such as high temperature plastic with good flame retardant performance for the shell, high conductivity materials such as copper and copper alloy for internal conductive parts, and high quality magnetic materials for electromagnetic components. Strict inspection and screening of raw materials to ensure their quality.

-

Test

Select high-quality raw materials that meet national standards, such as high temperature plastic with good flame retardant performance for the shell, high conductivity materials such as copper and copper alloy for internal conductive parts, and high quality magnetic materials for electromagnetic components. Strict inspection and screening of raw materials to ensure their quality.

-

Selection and inspection of raw materials

Select high-quality raw materials that meet national standards, such as high temperature plastic with good flame retardant performance for the shell, high conductivity materials such as copper and copper alloy for internal conductive parts, and high quality magnetic materials for electromagnetic components. Strict inspection and screening of raw materials to ensure their quality.

-

Processing and forming

Select high-quality raw materials that meet national standards, such as high temperature plastic with good flame retardant performance for the shell, high conductivity materials such as copper and copper alloy for internal conductive parts, and high quality magnetic materials for electromagnetic components. Strict inspection and screening of raw materials to ensure their quality.

-

Test

Select high-quality raw materials that meet national standards, such as high temperature plastic with good flame retardant performance for the shell, high conductivity materials such as copper and copper alloy for internal conductive parts, and high quality magnetic materials for electromagnetic components. Strict inspection and screening of raw materials to ensure their quality.

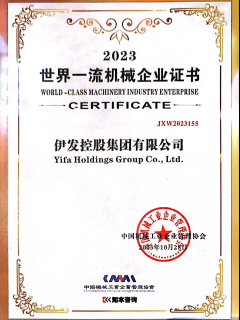

Qualification Certificate

2023 China Top 500 machinery

2023 China Top 500 machinery

ISO14001

ISO45001

RCBO CE

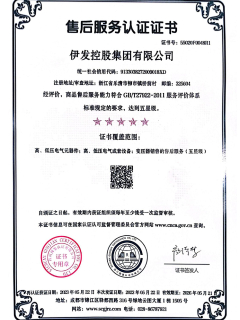

Qualification After-sales Service Certificate

OEM/ODM Service

The OEM/ODM services we provide cover the entire process of design, manufacturing, testing and delivery of electrical products. With advanced production equipment, strict quality management system and rich industry experience, we provide customized electrical product solutions to ensure that the performance and quality of the products reach the industry-leading level.

-

Industrial Design

-

Mold Development

-

Efficient Production

-

Quality Inspection And Control

-

Promotion And Publicity

-

After-sales Service

Service Process

-

01

Initial contact and understanding of needs

-

02

Demand analysis and plan formulation

-

03

Sample development and test verification

-

04

Quotation and contract signing

-

05

Mass production and quality control

-

06

Product packaging and logistics distribution

-

07

After-sales service and support

Sales Network

Our company focuses on the production and sales of electronic distribution equipment, the main products include distribution box, circuit breaker, substation, transformer and so on. In order to better serve the global market, our sales network covers multiple regions, especially in developing countries and emerging markets. We bring our products to market through multiple channels and are committed to providing our customers with high quality power distribution solutions. The specific sales network is as follows:

Sales Territory

Africa:

We have a solid market base in several countries in Africa, particularly in East, South and North Africa. With extensive industry experience and customized product design, we ensure timely delivery and efficient service through the cooperation of local agents and distributors.

Russia And The Middle East:

We are also actively expanding in Russia and the Middle East, especially in the context of growing demand for energy and infrastructure. Through cooperation with local enterprises, we provide tailor-made power distribution solutions for customers in these regions, and have established a stable sales channel and after-sales service network.

Partners And Distributors

We have established long-term strategic partnerships with major distributors and power equipment suppliers in many countries and regions, and are able to respond quickly to market demands and provide customers with personalized power distribution equipment solutions.

Distributors are not only responsible for sales, but also provide customers with technical support such as equipment installation, commissioning and post-maintenance to ensure long-term stable operation of products.

Sustainable Development

Yifa Holding Group has always adhered to the core concept of sustainable development, and is committed to actively fulfilling social responsibilities and promoting environmental protection and social welfare while pursuing economic benefits. We know that the long-term development of enterprises can not be separated from the harmonious coexistence with nature, therefore, we unswervingly embarked on the green, low-carbon, circular development road.

-

Green Manufacturing

Adopt advanced production processes and technologies, such as automated production lines and intelligent management systems, to reduce energy consumption and waste emissions.

Implement strict energy-saving and emission reduction measures, such as installing solar photovoltaic panels, optimizing lighting systems, etc., to reduce energy consumption. -

Circular Economy

Build a closed-loop industrial chain to promote the recycling of electrical products and the harmless treatment of waste. Recycling of waste electrical products, through dismantling, repair and reuse means to reduce resource waste. Promote the concept of circular economy and encourage employees and partners to participate in resource recovery and reuse activities.

-

Innovation-driven

Increase investment in research and development, promote technological innovation and product upgrades, and meet market demand with more efficient and environmentally friendly electrical solutions. Explore new energy fields, such as the use of renewable energy such as solar energy and wind energy, and inject new impetus into the sustainable development of enterprises. Intelligent management system is introduced to improve production efficiency and resource utilization through data analysis and optimization.

Concrete Measures For Sustainable Development

Energy-saving and emission reduction measures:

Formulate detailed energy conservation and emission reduction plans, clarify goals and responsibilities, and ensure that all measures are effectively implemented.

Promote energy-saving technologies and products to reduce energy consumption.

Encourage employees to save resources, such as reducing paper use, saving water, etc., to form a good atmosphere to save resources.

Environmental product development:

Increase investment in the research and development of environmental protection products, promote product upgrading and innovation, and improve the environmental performance and market competitiveness of products.

Third-party certification bodies are introduced to certify and evaluate environmentally friendly products to ensure that they meet environmental standards.

Promote the use of environmentally friendly products, and improve consumer awareness and acceptance of environmentally friendly products through publicity and education.

Social responsibility Practice:

Actively participate in social welfare activities, such as environmental protection publicity, poverty alleviation, etc., to give back to society.

Work closely with local governments and communities to promote sustainable development in the region.

Strengthen staff training and awareness raising, improve staff environmental awareness and responsibility.

Sustainable Development Results

-

Energy saving and emission reduction:

By implementing a series of energy conservation and emission reduction measures, we have successfully reduced energy consumption and carbon emissions, making positive contributions to the response to global climate change.

-

Social responsibility

We actively participate in social welfare activities and give back to the community through donations and volunteer services. We also work closely with local governments and communities to promote sustainable development in the region.

Future Outlook

Looking forward to the future, YIFA Holding Group will continue to uphold the concept of sustainable development, continuously increase investment in environmental protection, new energy and other fields, and promote the transformation and upgrading of enterprises and high-quality development. With a more open, inclusive and cooperative attitude, we will work with our global partners to meet challenges, share development opportunities, and contribute our wisdom and strength to the realization of the global Sustainable Development Goals.